-

Your shopping cart is empty!

3D MEASURING MACHINE – XO SERIES

Product Introduction

WENZEL’s 3D XO series measuring machines are the ideal solution for businesses that need accurate, easy-to-use and cost-effective measuring equipment. With a gantry design and the ability to integrate a variety of sensors, the XO series effectively meets the measurement requirements in production and quality control.

Specifications

- Structure: sloped shaft with Y-axis direction machined directly on the machine base, ensuring long-term stability.

- Control system: CNC with specialized measuring software.

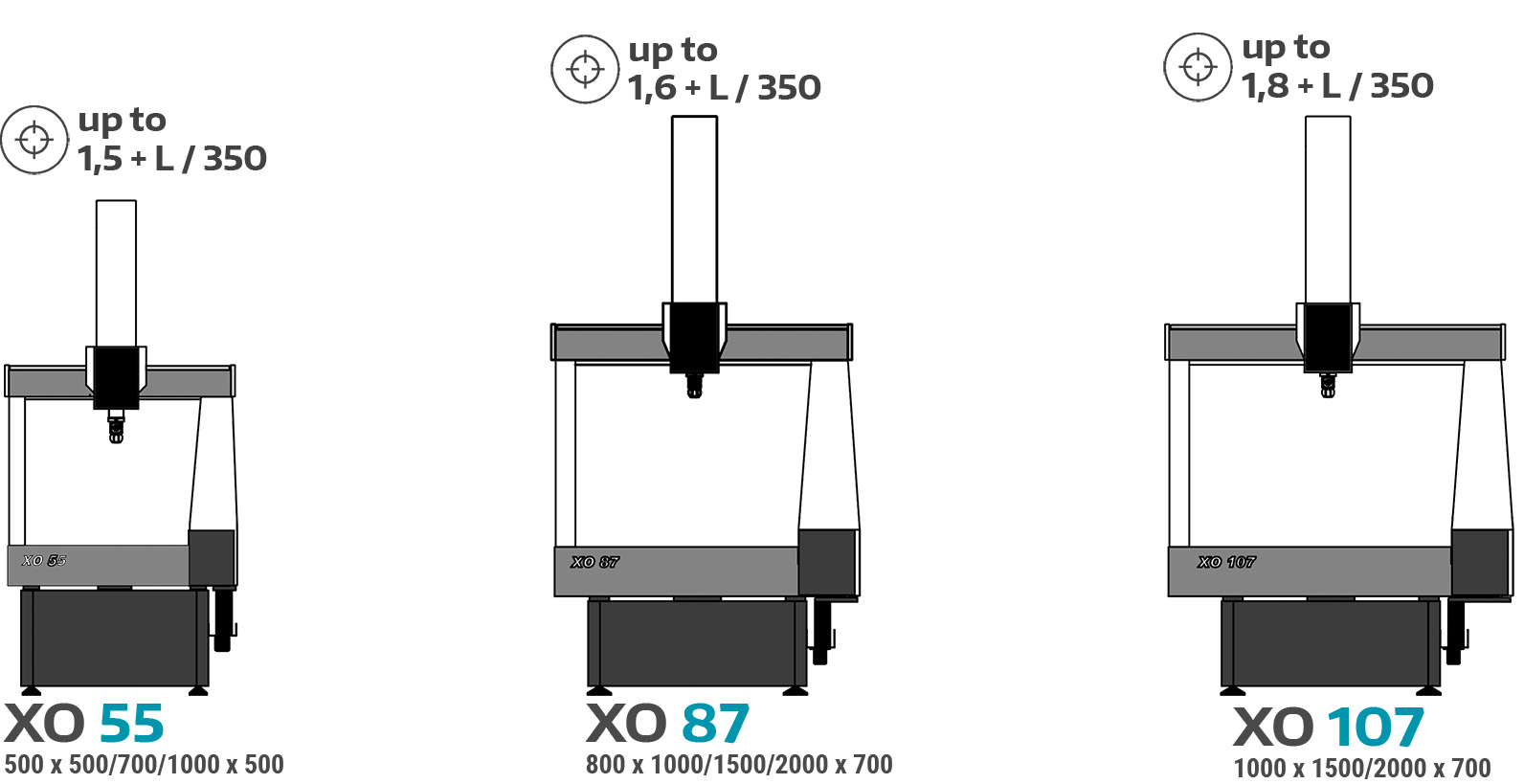

- Measuring size: optional model (Contact for detailed advice).

- Sensor: Supports Renishaw’s leading system lines such as PH20 5 axis, TP20, TP200, as well as optical sensors such as WM | LS 70 and SHAPETRACER 2.

- Accuracy: Meets industrial measurement standards, suitable for many different measurement applications.

Outstanding features

- Compact design, space saving, suitable for many working environments.

- Easy to operate user-friendly operations.

- Ability to integrate a variety of sensors, meeting many different measurement needs.

- Sturdy structure with granite, ensuring high stability and accuracy.

Benefits of use

- Increase product quality inspection efficiency.

- Reduce time and cost in the measurement process.

- Easy to integrate existing products.

- Meet the operation of measurement requirements from simple to complex.

Applications

- Automotive industry: Check the size and geometry of parts.

- Aerospace industry: Perform aircraft and mechanical parts.

- Machinery manufacturing industry: Precise inspection of mechanical parts.

- Production samples: Ensure the accuracy of samples and products.

Contact us now for detailed advice and promotions!

https://filterfinevn.com/lien-he/

Reference link: https://www.wenzel-group.com/en/products/xo-baureihe#datenblatt