-

Your shopping cart is empty!

COMPARE THE SUPERIORITY OF LEVITRONIX PUMP IN CHEMICAL MECHANICAL PLANARIZATION (CMP)

Tuesday April 16th, 2024

-

0 lượt xem

COMPARE THE SUPERIORITY OF LEVITRONIX PUMP IN CHEMICAL MECHANICAL PLANARIZATION (CMP)

Chemical Mechanical Planarization (CMP) must continuously improve to meet the stringent requirements of next generation IC device manufacturing. The consistency of the slurry is essential to achieve high process repeatability and uniformity. Compared to Levitronix® pumps, pneumatic pumps can cause shear stress due to check valves and other components. Shear stress in pumps can cause slurry agglomeration. Agglomerated slurry particles can lead to micro scratches, which cause wafer defectivity in CMP. Furthermore, Slurry agglomerates result in quick filter clogging, leading to increased maintenance costs.

Reduced Slurry Agglomeration

Low shear pump principle

The magnetic levitation technology guarantees that no pump components contact one another, enabling the gentle processing of delicate slurries. The smooth wetted plastic surfaces and the absence of a mechanical bearing, narrow gaps, fissures, and dead-zones ensure the highest standards of slurry health during its lifecycle.

Facts

In comparison to Levitronix® pumps, pneumatic pumps can cause shear stress due to check valves and other components. Shear stress in pumps can cause slurry agglomeration. Agglomerated slurry particles can lead to micro scratches causing wafer defectivity in CMP.

Test conditions

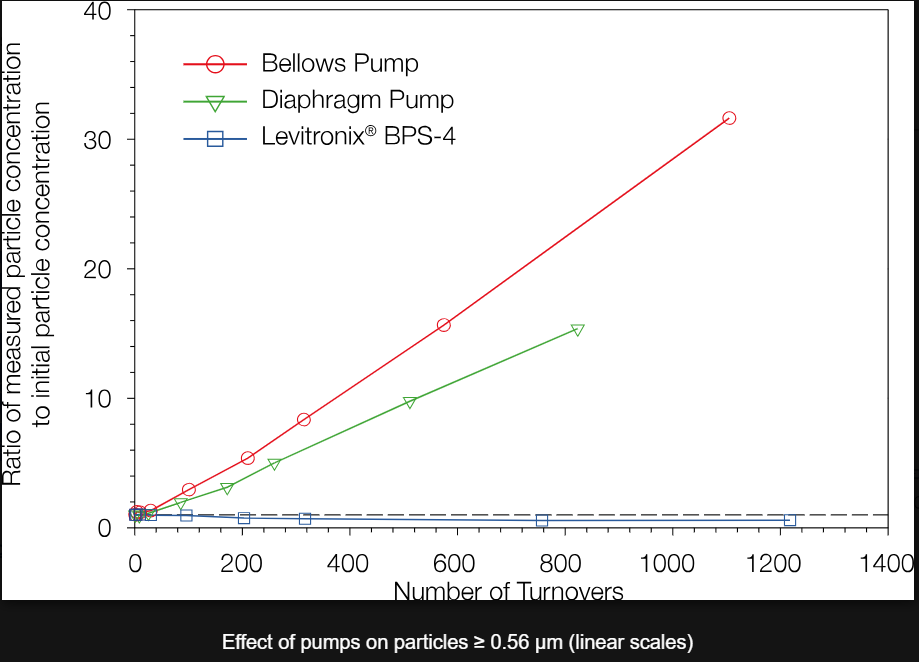

A Levitronix® BPS-4 pump, a diaphragm pump, and a bellows pump were evaluated for their effect on the health of Cabot Semi-Sperse® 12 slurry. A fixed volume of slurry was recirculated at 30 lpm and 2.1 bar, and samples were drawn from the system at selected times for analysis. The particle size distribution of each sample was measured and the increase in particle concentration relative to the initial concentration was compared.

Results

Little change in the particle size distribution was observed with Levitronix® pumps, regardless of particle size. With bellows and diaphragm pumps, significant increases particularly in the large particle concentrations were observed.

Increased Filter Lifetime

Reduced clogging caused by slurry agglomerates

The lifetime of a CMP filter is directly linked with the concentration of large particles in the slurry. As the concentration of large particles of CMP slurry tends to increase in bellows and diaphragm pumps, the filter lifetime can be significantly prolonged with Levitronix® pumps.

Facts

In a previous test, the concentration of large particles of CMP slurry tends to increase in bellows and diaphragm pumps, whereas no increase was observed with a Levitronix® pump.

Large particles can lead to filter clogging, which results in a decreased filter lifetime.

Test conditions

A Levitronix® BPS-4 pump, a diaphragm pump, and a bellows pump were evaluated for their effect on filter lifetime. Each pump was used to circulate approximately 28.5 liters of Cabot Semi-Sperse® 12 slurry at a flow rate of approximately 29.5 lpm (7.8 gpm). A 10” Mykrolis Planargard® CMP3 filter was installed downstream of each pump. The pressure drop across each filter, representing a correlate of filter lifetime, was monitored and compared. The tests were continued until the pressure drop across the filter increased by at least 10 psig or more than 10,000 turnovers were achieved.

Results

The pressure drop measured with the bellows and diaphragm pumps were approximately 15 and 5 times higher than those experienced with the Levitronix® pump. The Levitronix® pump was the only pump to reach 10,000 turnovers without the pressure drop increasing to 10 psig.

Tin liên quan

- CUSTOMER SUCCESS PROGRAM – THE LIGHTHOUSE SOLUTION FOR ENHANCED CLEANROOM MONITORING PERFORMANCE

- NOTICE: CHANGES TO DUPONT’S LEGAL ENTITY AND BANK ACCOUNT INFORMATION EFFECTIVE FROM OCTOBER 1, 2025

- Discover the Handheld Airborne Particle Counter – The Efficient Solution for Air Quality Monitoring

- Gantry technology from WENZEL

- Understanding the Ultra Pure Water Process