-

Your shopping cart is empty!

Kalrez® RGD Sealing Solutions for the Oil and Gas Industry

Tuesday December 23rd, 2025

-

0 lượt xem

In high-pressure, high-temperature (HPHT) oil & gas operations, elastomer failure caused by Rapid Gas Decompression (RGD) represents a major risk to equipment integrity and operational safety. When elastomer seals absorb gas under high pressure, sudden depressurization can lead to blistering, cracking, and catastrophic seal failure, resulting in unplanned downtime, equipment damage, and significant operational hazards.

What is Kalrez® RGD?

Kalrez® RGD is a family of high-performance perfluoroelastomer (FFKM) materials developed by DuPont™, specifically engineered for oil & gas, petrochemical, and energy applications operating under extreme conditions. These materials are designed to deliver exceptional resistance to rapid gas decompression, ensuring reliable sealing performance even during aggressive pressure cycling.

Key Advantages of Kalrez® RGD

✔ Industry-Leading RGD Resistance

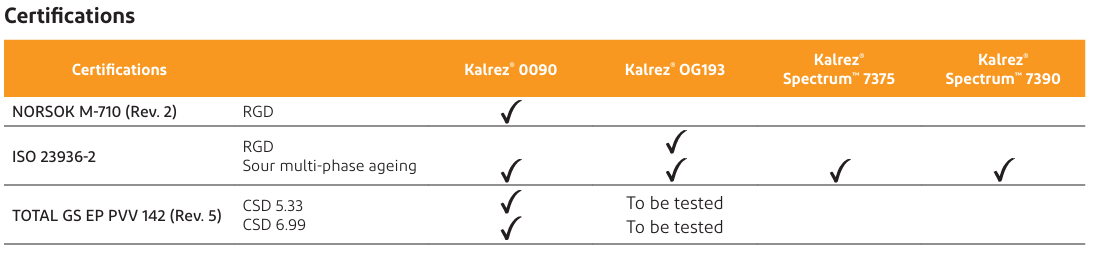

Kalrez® RGD compounds comply with stringent industry standards such as NORSOK M-710 and ISO 23936-2, effectively preventing blistering and seal damage during rapid decompression events.

✔ Exceptional Chemical & Thermal Stability

Kalrez® RGD maintains long-term performance in harsh environments involving high-pressure CO₂, H₂S, methane, and sour gas, as well as aggressive process chemicals.

✔ Extended Service Life

By significantly reducing seal replacement frequency, Kalrez® RGD helps minimize maintenance costs, downtime, and safety risks, improving overall equipment reliability.

Typical Applications of Kalrez® RGD

- Downhole Tools – Resistant to HPHT conditions and aggressive well fluids

- Wellhead Seals – Long-term reliability at critical sealing points

- Valves, Pumps & Compressors – Leak prevention and stable operation

- Hydraulic & Pneumatic Systems – Durable performance under high dynamic loads

Featured Kalrez® RGD Products

Kalrez® OG193 – Best-in-Class RGD Resistance

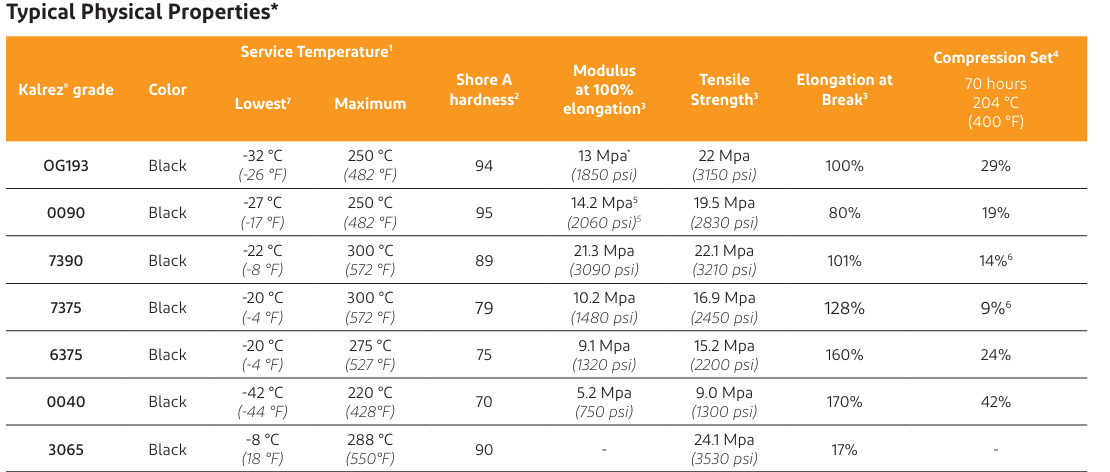

Kalrez® OG193 perfluoroelastomer components offer an outstanding balance of properties for demanding oil & gas applications. This compound combines best-in-class RGD performance with excellent chemical resistance, thermal stability, and low-temperature flexibility.

Kalrez® OG193 is highly versatile and suitable for a wide range of critical sealing components, including O-rings, packers, bonded seals, chevron stacks, T-seals, and more. It is an ideal solution for both upstream and downstreamapplications such as well completion equipment, wireline and drilling tools, pumps, mechanical seals, valves, and compressors.

Chemical Resistance:

Kalrez® OG193 resists chemicals commonly encountered in oil & gas operations, including sour service fluids containing H₂S, and meets ISO 23936-2 multiphase sour aging requirements with 10% H₂S up to 215 °C.

Kalrez® 0090 – Superior Deformation & RGD Resistance

Kalrez® 0090 provides robust and reliable sealing solutions for applications requiring excellent RGD resistance, high hardness, high modulus, and exceptional extrusion resistance, even without backup rings.

Typical oil & gas applications include downhole drilling and completion tools, as well as industrial equipment such as pumps, valves, and compressors.

Kalrez® 0090 has been independently certified by two laboratories to meet stringent RGD resistance criteria. In addition to proven RGD performance, it delivers outstanding chemical and thermal resistance.

Chemical Resistance:

Kalrez® 0090 resists oil & gas process chemicals, including H₂S-containing fluids, and complies with ISO 23936-2 multiphase aging requirements with 10% H₂S up to 225 °C.

Kalrez® Spectrum™ 0040 – Low-Temperature Performance

Kalrez® Spectrum™ 0040 is specifically designed for low-temperature environments where high chemical resistance is required. Low-temperature sealing performance down to -42 °C, typically unattainable with standard FFKM materials, is achievable with Kalrez® 0040.

This compound is an excellent choice for chemical transportation couplings and other applications requiring elasticity and chemical resistance in extremely cold conditions.

Kalrez® Spectrum™ 6375 – Broadest Chemical Resistance

Kalrez® Spectrum™ 6375 was developed for the chemical processing industry to deliver outstanding performance across the widest range of chemicals and temperatures.

It is well-suited for exposure to acids, bases, amines, steam, pure ethylene oxide, and many other aggressive chemicals. The advanced curing system supports a maximum continuous service temperature of 275 °C (527 °F), enhancing chemical resistance across all temperature ranges and during process temperature excursions.

Kalrez® Spectrum™ 7375 – High Temperature & Hot Water/Steam Resistance

Kalrez® Spectrum™ 7375 is an innovative FFKM material based on a patented crosslinking system, designed for chemical processing applications requiring broad chemical resistance and hot water/steam compatibility at elevated temperatures.

This compound offers excellent compression set resistance, superior physical property retention, and strong mechanical performance. Its outstanding electrical insulation properties make it ideal for harsh oil & gas applications such as electrical connectors and boots.

The recommended maximum service temperature is 300 °C.

Contact for Kalrez® RGD Technical Consultation & Quotation

Filterfine Vietnam – Official distributor of DuPont™ Kalrez® products in Vietnam.

We provide high-performance FFKM sealing solutions along with expert technical support to help customers optimize equipment reliability and meet stringent industry standards.

🌐 Website: https://filterfinevn.com

📞 Hotline: 0961.152.844

💬 Zalo OA: https://zalo.me/3662661132832477703

Tin liên quan

- FILTERFINE VIETNAM ANNOUNCES LUNAR NEW YEAR HOLIDAY SCHEDULE 2026

- Next-Generation Photochemical Filters for Semiconductor Manufacturing

- WM | Quartis R2026-1 – The Latest CMM Coordinate Measuring Software from WENZEL

- Cleanrooms and Innovations in Enhancing Operational Efficiency

- Particle Monitoring – A Critical Foundation for Quality and Compliance in Modern Manufacturing